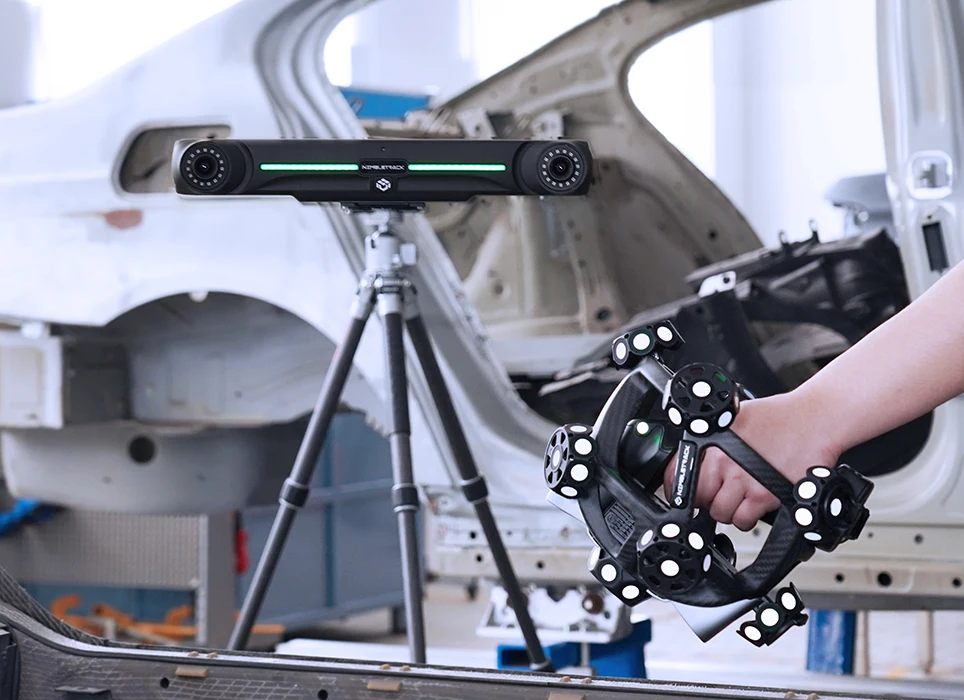

Portable Metrology-Grade Optical Measurement System

The NimbleTrack is a wireless 3D scanner designed as a portable 3D scanner for inspection, quality control and reverse engineering—delivering metrology-grade accuracy without the restriction of cables.

Overview

The NimbleTrack Wireless 3D Scanner is a next-generation optical measurement solution for teams that need a high accuracy portable 3D scanner with complete freedom of movement. Featuring a fully wireless design, advanced blue-laser scanning technology and integrated edge computing, NimbleTrack supports fast, repeatable data capture for inspection environments and field measurement.

Unlike traditional tethered scanners, NimbleTrack removes the limitations of cables and external processing hardware. This makes it ideal as a wireless metrology 3D scanner for dimensional verification, on-site measurement and 3D scanning system for reverse engineering workflows across modern manufacturing.

Key Features & Benefits

True Wireless Operation

- No data cables or external power supplies

- Rapid deployment on the shop floor or at customer sites

- Improved operator safety and ergonomics

Metrology-Grade Accuracy and Stability

NimbleTrack is engineered for metrology applications where repeatable, reliable measurement matters—making it a strong choice as a 3D scanner for quality control and tolerance verification.

- Scanner accuracy up to 0.020 mm

- Volumetric accuracy up to 0.064 mm

- Suitable for GD&T inspection and verification

Advanced Blue-Laser Scanning Technology

- Up to 50 laser lines

- High-density surface capture for detailed meshes

- Excellent performance on reflective and dark surfaces

High-Speed Edge Computing

- Up to 120 FPS real-time processing

- Reduced scanning cycle times

- Smooth data capture and tracking

Compact, Lightweight and Rugged Design

- Carbon fibre structural frame

- Compact head for confined access

- Reduced operator fatigue for prolonged scanning sessions

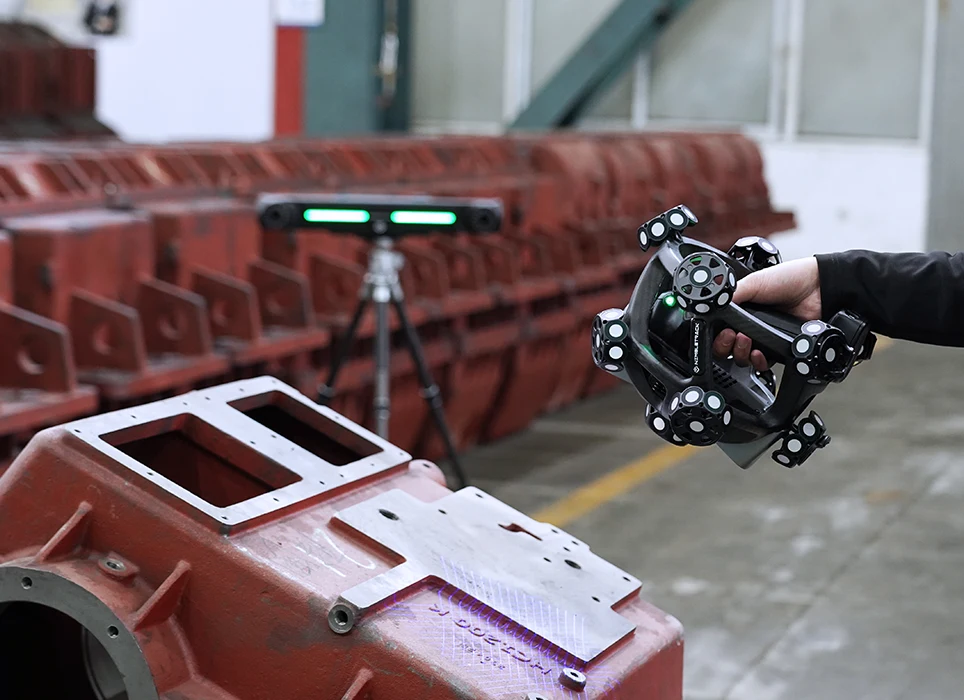

Typical Applications for Inspection and Reverse Engineering

- Dimensional inspection and quality control using a portable 3D scanner for inspection

- Reverse engineering with a high accuracy portable 3D scanner to create CAD-ready meshes

- Deviation analysis for CAD comparison and process validation

- Tooling and fixture inspection to verify jigs, moulds and forming tools

- On-site measurement for large or fixed components where cable-free use matters

Commonly used across automotive, aerospace, power generation, heavy engineering, mould & die and precision manufacturing— including customers searching for an industrial 3D scanner UK supply and support partner.

Specifications

| Specification | Value |

|---|---|

| Scanning Technology | Blue laser multi-line scanning |

| Laser Lines | Up to 50 |

| Accuracy | Up to 0.020 mm |

| Volumetric Accuracy | Up to 0.064 mm |

| Frame Rate | Up to 120 FPS |

| Scan Area | Approx. 500 × 600 mm |

| Output Formats | STL, OBJ, PLY, IGS |

| Laser Safety | Class II |

Talk to Our Team

📞 +44 (0) 7968 182791

📧 sales@cmm-solutions.co.uk