Wireless, Large-Scale Optical 3D Scanning

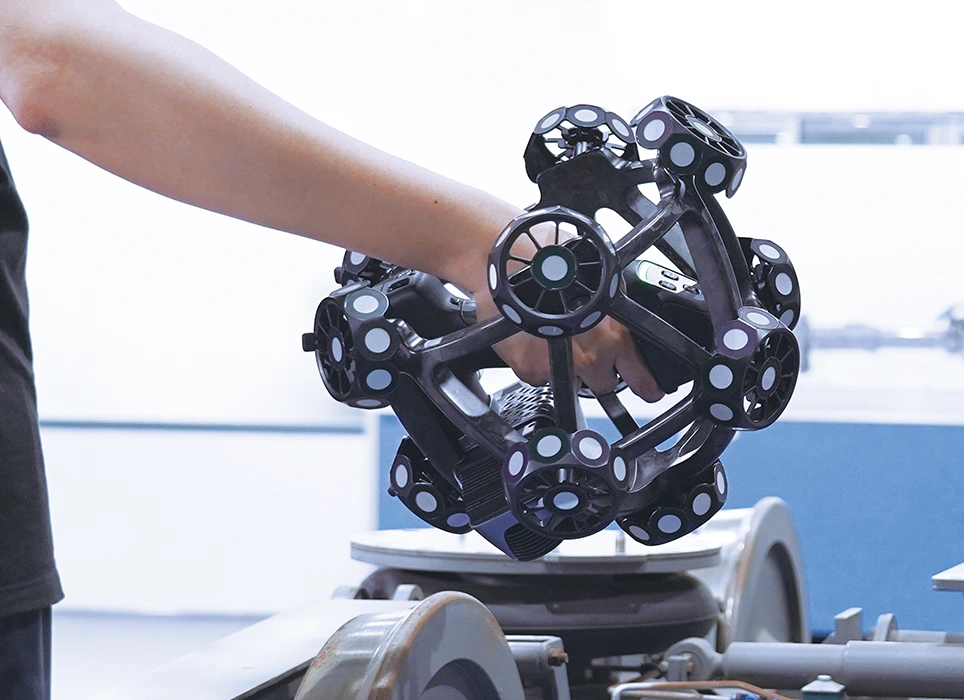

TrackScan Sharp-S is a wireless large-scale 3D scanner engineered for fast, reliable measurement of large parts without cables. Designed for metrology-grade inspection and large volume 3D scanning, it delivers high-speed data capture and stable tracking for efficient quality control workflows.

Overview

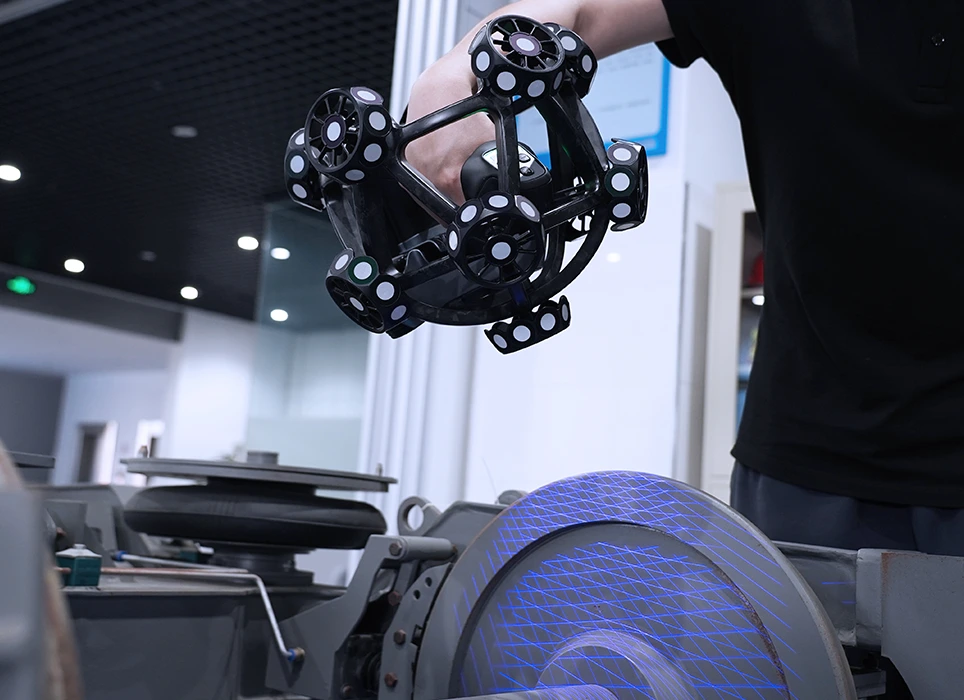

TrackScan Sharp-S is built to streamline inspection of large and complex parts by combining long-range optical tracking with high-speed blue-laser scanning. With a tracking distance of up to 8.5 metres and a large measurement volume (up to 135 m³), the system reduces the need for frequent repositioning—supporting efficient measurement of large components from fewer setups.

This system is ideal for teams looking for an optical 3D scanning system that can support fast production checks, dimensional verification, and deviation analysis in aerospace, automotive, power & energy, heavy engineering and large fabrication environments.

For applications requiring contact probing of holes or hidden points, TrackScan Sharp-S can be expanded with the optional I-Probe accessory (contact probing module). The I-Probe seamlessly integrates with the optical tracking system, enabling precise capture of features such as hole centres, edges and slots for GD&T and feature-based inspection workflows.

Key Features & Benefits

Ultra-Fast 3D Measurements

- Measurement rate up to 4,860,000 measurements per second

- Large scanning window up to 800 × 700 mm for rapid coverage

- Designed to accelerate large volume 3D inspection cycles

Long-Distance, Large-Volume Tracking

- Maximum tracking distance up to 8.5 m

- Measurement volume up to 135 m³; effective measurement range up to 233 m³

- Reduced need for tracker repositioning on large components

Wireless Freedom for On-Site and Shop-Floor Use

- Wireless operation improves mobility and access around large parts

- Minimises cable management and improves operator ergonomics

- Suitable for factory environments, large assemblies and field work

Intelligent Edge Detection

- Supports precise feature inspection on holes, slots, rectangles, rivets and edges

- Designed for fast capture of hole position and diameter for inspection tasks

- Helpful for feature-based quality control and dimensional verification

Optional I-Probe Contact Probing

- Integrates with optical tracking for high-precision contact measurement

- Ideal for feature-based inspection and GD&T workflows

- Enables capture of holes, edges, slots and concealed points with excellent repeatability

Typical Applications for Large-Scale Inspection

- Large-part dimensional inspection and 3D scanner for quality control workflows

- Deviation analysis and CAD comparison for production verification

- Reverse engineering of large assemblies and fabricated structures

- Feature-based inspection using TrackScan with I-Probe for GD&T verification

- On-site measurement where wireless mobility improves productivity

If you’re searching for a wireless large-volume 3D scanner in the UK with application support and technical training, CMM Solutions can help configure the right system for your inspection requirements.

Specifications

| Specification | Value |

|---|---|

| Type | TrackScan-Sharp S |

| Scan Modes | Ultra-fast: 81 blue laser lines; Hyperfine: 17 blue parallel lines; Deep hole: 1 blue laser line |

| Accuracy | 0.025 mm |

| Measurement Rate | 4,860,000 measurements/s |

| Scanning Area | 800 × 700 mm |

| Laser Class | Class II (eye-safe) |

| Resolution | 0.020 mm |

| Volumetric Accuracy |

10.4 m³ (Tracker 3.5 m): 0.048 mm With MSCAN-L15 – 35 m³ (5.2 m): 0.069 mm With MSCAN-L15 – 95 m³ (7.2 м): 0.128 мм With MSCAN-L15 – 135 m³ (8.5 м): 0.159 мм |

| Stand-off Distance | 300 mm |

| Depth of Field | 400 – 800 mm |

| Output Formats | .stl, .ply, .obj, .igs, .wrl, .xyz, .dae, .fbx, .ma, .asc |

| Operating Temperature | -10 °C to 40 °C |

| Interface | USB 3.0, Network Interface |

| Optional Accessories |

I-Probe contact probing module Portable CMM T-Probe (repeatability 0.030 mm) |

Performance depends on configuration, calibration and application conditions.

Why Buy from CMM Solutions?

- UK-based application advice and system configuration

- On-site demonstrations, training and commissioning

- Support integrating TrackScan and I-Probe into your inspection workflow

- Ongoing technical support and after-sales assistance

Talk to Our Team

📞 +44 (0) 7968 182791

📧 sales@cmm-solutions.co.uk